Heavy Fabricated Gates

Home / Heavy Fabricated Gates

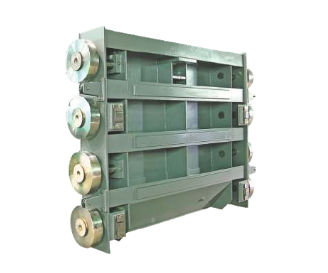

Bulkhead gates are a cost-effective way for dewatering channels. They are large fabricated gates used to close the waterway for maintenance of the downstream equipment in most cases. These gates are custom designed for specific applications in almost any size. Stacking gates also permits flow control for larger openings.

The term bulkhead gate can be used to describe what is essentially very large slide gate or to describe a device used like stop logs but providing significantly fewer handling iterations. Bulkhead gates are usually installed and removed under balanced head conditions. In case if it is not possible to fill downstream area to achieve balance head condition, Bulkhead gate will be designed for crack opening considering higher operating capacity of lifting mechanism.

These gates are offered in various materials of construction such as Carbon steel / Stainless steel / Super Duplex stainless steel etc. to suit the intended application. These gates can be operated with electric, pneumatic or hydraulic, cable operating systems.

SERIES : A-511 / 512 / 513– STAINLESS STEEL BULK HEAD SLIDE GATES

- Opening Size range: 900X900 mm to 4500X4500 mm Higher sizes on request

- Head Range: Upto 30 m seating & Upto 30 m unseating

- Applicable Standards: As per Jash design

- Mounting: Side wall embedded (A-511), Side Wall Anchored (A-512), Face Wall Anchored (A-513)

- Sealing system: Resilient Sealing System

SERIES : A-521 / 522 / 523– ALUMINIUM BULK HEAD SLIDE GATES

- Opening Size range: 900X900 mm to 4500X4500 mm Higher sizes on request

- Head Range: Upto 10 m seating & Upto 10 m unseating

- Applicable Standards: As per Jash design

- Mounting: Side wall embedded (A-521), Side Wall Anchored (A-522), Face Wall Anchored (A-523)

- Sealing system: Resilient Sealing System

SERIES : A-531 / 532 / 533– STAINLESS STEEL BULK HEAD SLIDE GATES

- Opening Size range: 900X900 mm to 4500X4500 mm Higher sizes on request

- Head Range: Upto 30 m seating & Upto 30 m unseating

- Applicable Standards: As per Jash design

- Mounting: Side wall embedded (A-521), Side Wall Anchored (A-522), Face Wall Anchored (A-523)

- Sealing system: Resilient Sealing System

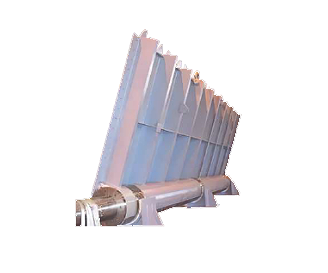

Roller gates are flat gates operated vertically and are made up of skin plate supported by vertical and horizontal ribs along with rollers or wheels transferring water thrust on rails or tracks embedded in concrete. Roller gates are used for flood control jobs, irrigation jobs, industrial water control jobs, dams, water treatment plants, sewage treatment plants & power plants etc. Roller gates are designed to control flow and reduce operating Loads for Large openings, high head applications or where frequent operation is required.

These gates are offered in various materials of construction such as Stainless steel / Super Duplex stainless steel / Structural steel etc. to suit the intended application. These gates can be operated with electric, hydraulic and cable operating systems.

SERIES : A-515 – STAINLESS STEEL ROLLER GATES

SERIES : A-535– STRUCTURAL STEEL ROLLER GATES

- Opening Size range: up to 6000X6000 mm, Higher sizes on request

- Head Range: Upto 60 m seating & Upto 60 m unseating

- Applicable Standards: As per Jash design

- Mounting: Side wall embedded, Side Wall Anchored, Face Wall Anchored

- Sealing system: Resilient Sealing System

Crest Gates are used for flow and level control, with an established reputation for Long life and low maintenance in a wide range of applications. They pivot down to open operating around a hinge mounted just downstream of the top of the dam. Typically, they are quite long and not tall although they can be slightly to the other side of square. Crest gates modulate for full range of travel from fully closed to fully open for precise control in water and wastewater application. The Bascule® and Pelican• designs were acquired from Allis-Chalmers in 1990 and now belong to our subsidiary company in USA.

These gates are offered in various materials of construction such as Stainless steel / Super Duplex stainless steel / Structural steel etc. to suit the intended application. These gates can be operated with electric and hydraulic operating systems.

SERIES:A-711- Bascule® Gate Design Stainless Steel Crest Gates.

SERIES:A-731- Bascule® Gate Design Structural Steel Crest Gates.

SERIES:A-712- Pelican® Gate Design Stainless Steel Crest Gates.

SERIES:A-732- Pelican® Gate Design Structural Steel Crest Gates.

- Opening Size range: up to 9000X3600 mm Square, rectangular & higher sizes on request

- Head Range: Upto 60 m seating & Upto 60 m unseating

- Applicable Standards: As per Jash design

- Sealing system: Resilient Sealing System

Butterfly gates are normally used for Sewage treatment plants, Water filtration plants, Power plants, industrial water control jobs applications. Butterfly gates are sturdily designed for long life and low maintenance in difficult conditions, but also incorporate field-adjustment features.

Jash butterfly gates have bubble – tight shutoff, stainless steel to resilient sealing, three side and four side sealing options, self-lubricating bushings and two-way adjustable thrust bearings. Specially designed vane reduces turbulence and strengthens assembly.

These gates are offered in various materials of construction such as Stainless steel / Super Duplex stainless steel / Structural steel etc. to suit the intended application. These gates can be operated with manual and electric actuator.

SERIES : A-911 – STAINLESS STEEL BUTTERFLY GATES

SERIES : A-931 – STRUCTURAL STEEL BUTTERFLY GATES

- Opening Size range: up to 3000X6000 mm Square, rectangular & higher sizes on request

- Head Range: Upto 10 m seating & Upto 10 m unseating

- Applicable Standards: As per Jash design

- Mounting: Side wall embedded, Side Wall Anchored, Face Wall Anchored

- Sealing system: Resilient Sealing System

Radial or Tainter gates are the curved gates storing water on its convex side. These gates are used for flood control jobs, irrigation jobs, industrial water control jobs, Dams, water treatment plants, sewage treatment plants & power plants etc. Jash Tainter gates are normally used to control the flow of water or wastewater over a dam or drainage structure to provide a wide and unobstructed opening. These gates, which are sometimes very large, are sturdily designed for long Life and low maintenance in difficult conditions, but also incorporate a number of “designed-in,” installation & field-adjustment features.

Tainter gates offer advantages over other type of gates such as self-closing during operation, lesser lifting capacity, minimal vibration under operation, least flow turbulence and possibility of larger size construction.

These gates are offered in various materials of construction such as Stainless steel / Super Duplex stainless steel / Structural steel etc. to suit the intended application. These gates can be operated with electric, hydraulic and cable operating systems.

SERIES:A-715- Stainless Steel Radial / Tainter Gates.

SERIES:A-735- Structural Steel Radial / Tainter Gates.

- Opening Size range: up to 9000X3600 mm Square, rectangular & higher sizes on request

- Head Range: Normally up to 5 m or depending upon client’s requirement

- Applicable Standards: As per Jash design

- Mounting: Trunnion mounted

- Sealing system: Resilient Sealing System

As name refers, Miter gates are made up of two gate leaves that provide closure at a “miter” or angle pointed towards the upstream side of water flow. The miter gates are normally used to shut off flow at a navigational lock or in a waterway for maintenance of downstream equipment or to protect against flooding. These gates are standard in navigation locks because they provide a completely unobstructed flow path when open. Their simple construction offers long service life and low maintenance. Miter gates are designed for flow or pressure in only one direction.

Miter gates can be manufactured in carbon steel, stainless steel, and duplex stainless steel depending on the corrosiveness of the media and desired length of service life. Miter gates have resilient seals of neoprene and EPDM. Smaller gates can be operated manually with a bevel or worm gear drive and larger gates by hydraulic actuators.

SERIES: A-812 Stainless Steel Miter Gates

SERIES: A-832 Structural Steel Miter Gates

- Opening Size range: Up to 12700 x 9000 mm, higher sizes on request

- Head Range: Up to gate height

- Applicable Standards: As per Jash design

- Mounting: Side Wall Embedded

- Sealing system: Resilient Sealing System

Swing gates are flat gates pivoted at one end allowing rotation through 90 degrees / 180 degrees and are made up of skin plate supported by vertical and horizontal ribs. These gates used to protect against flooding or to dewater sections of a waterway for maintenance. They may be referred to as road closure gates because they most often seal a road cut in a levee. This type of gate, like miter gates, is designed for pressure in only one direction. Its simple construction and operation provide long service life with low maintenance.

Swing gates can be manufactured in carbon steel, stainless steel, and duplex stainless steel depending on the corrosiveness of the media and desired length of service life. Swing gates have resilient seals of neoprene or EPDM.

Smaller gates can be maneuvered by a few people manually and in rare cases, a manual worm gears are used to rotate the gates. Electric Motor operation and Cylinder actuation are both possible to operation these gates.

SERIES: A-811 Stainless Steel Swing Gates

SERIES: A-831 Structural Steel Swing Gates

- Opening Size range: Up to 15240 x 4572 mm, higher sizes on request

- Head Range: Up to gate height

- Applicable Standards: As per Jash design

- Mounting: Side Wall Embedded / Side Wall Mounted / Face Wall Mounted

- Sealing system: Resilient Sealing System

The tilting weir gate is having a flat skin plate reinforced with vertical and horizontal members fitted with a single torque tube across the invert. These gates are normally used to control the water level on irrigation canals, reservoirs, and drainage canals. These gates, which are sometimes very large, are designed for long life and low maintenance in difficult conditions, but also incorporate several “designed-in,” installation, and field-adjustment features.

As name refers, gate leaf of the tilting weir gate is tilted towards downstream side of reservoir or canals which facilitates to operate gate with minimal opening force.

Tilting weir gates can be manufactured in carbon steel, stainless steel, and duplex stainless steel depending on the corrosiveness of the media and desired length of service life. They have resilient sealing arrangement.

SERIES: A-315 Stainless steel construction, embedded in sidewalls

A-316 Stainless Steel construction, face or head wall mounted

A-335 Structural Steel construction, embedded in sidewalls

A-336 Structural Steel construction, face or head wall mounted

A-345 HDPE construction, embedded in sidewalls

A-346 HDPE construction, face or head wall mounted

SERIES: A-315/316/335/336/345/346 Tilting Weir Gate

- Opening Size range: Up to 9000 x 3000 mm, higher sizes on request

- Head Range: Up to gate height

- Applicable Standards: As per Jash design

- Mounting: Side Wall Mounted / Face Wall Mounted

- Sealing system: Resilient Sealing System

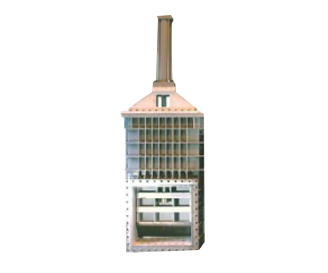

Bonneted gates are normally used for regulating flow in dam outlet works and remove silt through flushing tunnel. It is a completely enclosed slide gate that is designed and manufactured to be embedded (except for the actuator) in concrete. These gates are used for high water head application and extreme abrasive environment.

A Bonneted Gate consists of a vertically sliding disc, bonnet body, bonnet, bonnet cover, upstream and downstream transition sections, one or more conduit Liner sections, and an actuator. Bonneted gates are often supplied with paired gates and both upstream and downstream transition sections. This entire assembly is often embedded in the primary concrete pour deep in the dam. While this provides unsurpassed structural support, it makes gate replacement impossible. From a practical perspective, only the slide can be serviced without extraordinary efforts.

These gates are offered in various materials of construction such as Stainless steel / Super Duplex stainless steel / Structural steel etc. to suit the intended application. These gates can be operated with electric and hydraulic operating systems.

SERIES:A-915- Stainless Steel Bonneted Gates

SERIES:A-935- Structural Steel Bonneted Gates

- Opening Size range: 1200×1200 mm to 3600X3600 mm Square, rectangular & higher sizes on request

- Head Range: up to 150 m

- Applicable Standards: As per Jash design

- Mounting: Side wall embedded

- Sealing system: Resilient Sealing System