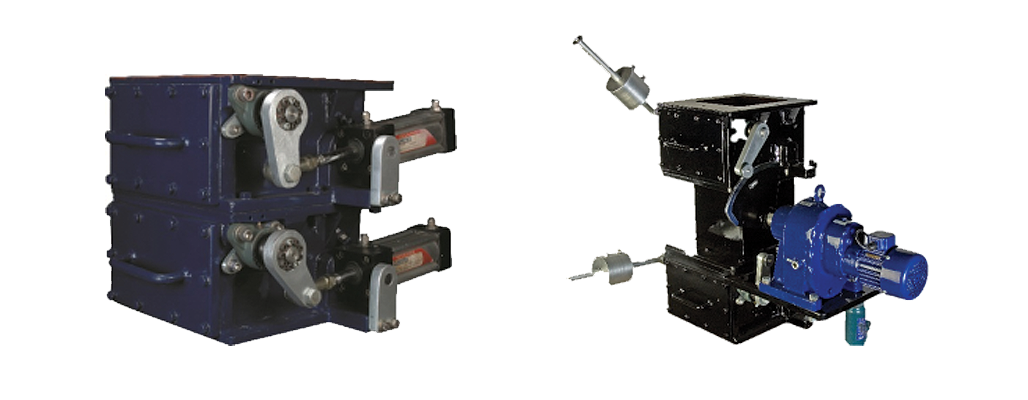

Double Flap Valve

Home / Bulk Solid handling Valves / Double Flap Valve

SERIES: C-401, DFG – Metal seated valve with replaceable cone & flapper – Cast Iron construction

Application

These valves are ideal for an airlock, batching, or metering application in free-flowing and abrasive bulk materials. These are specially designed to prevent bridging of material in the valve and enable in-situ replacement of seat and flapper. Seat and flapper are hardened to withstand abrasion and provide durabaility. Airlock is maintained by precision lapped seat and flapper by elimination any air leakages. These valves are offered in short height for space tight installations.

Size Range

200 (8”) SQ. – 400 (16”) SQ. Higher sizes on request

Flow rate

1.0 to 4.5 m³/hr, depending upon the size

Pressure Rating

PN3 (45 PSI)

Temperature Range

-20°C to 800°C

Flange drilling

As per Our standard

Optional features

Spool piece for capacity enhancement

Mode of operations

Counterweight, pneumatic, geared motor

Technical Features

Click to open

Drawing & Data Sheet

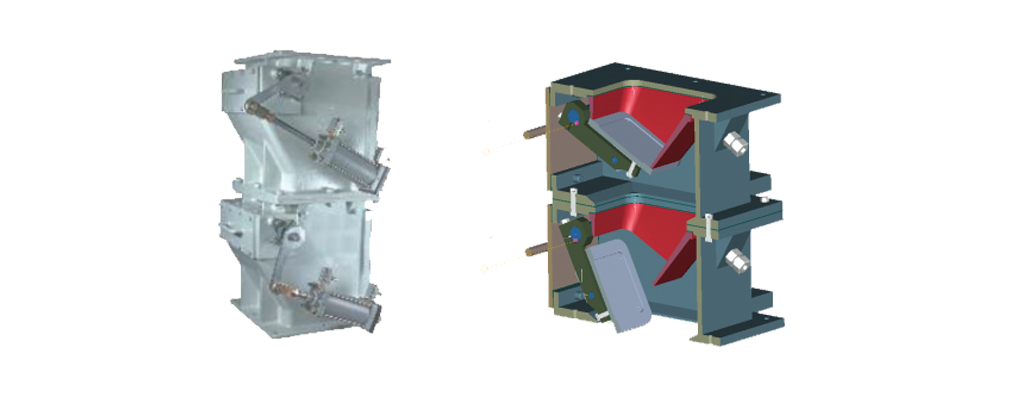

SERIES: C-402, DFG – Metal seated valve with replaceable cone & flapper – Cast Iron construction

Application

These valves are ideal for an airlock, batching, or metering application in free-flowing and abrasive bulk materials. These are specially designed to prevent bridging of material in the valve and enable in-situ replacement of seat and flapper. Seat and flapper are hardened to withstand abrasion and provide durabaility. Airlock is maintained by precision lapped seat and flapper by elimination any air leakages. These valves are offered in short height for space tight installations.. These are provided with increased height to handle a higher flow rate.

Size Range

200 (8”) SQ. – 300 (12”) SQ. Higher size on request

Flow rate

2.50 to 8.0 m³/hr, depending upon the size

Pressure Rating

PN3 (45 PSI)

Temperature Range

-20°C to 800°C

Flange drilling

As per Our standard

Optional Features

Spool piece for capacity enhancement

Mode of operations

Counterweight, pneumatic, geared motor

Technical Features

Click to open

Drawing & Data Sheet