Screw Conveyors

Home / Screw Conveyors

Screw Flight Forming

Helical Screw Flight Forming

Description

The Right Fit

The TruHelix™ Helical Screw Flight Forming System that encompasses both the intelligence of a proprietary software suite, and the tooling and machines that have been developed through the deep engineering knowledge of our highly experienced team of helical screw flight design and manufacturing experts. In the past, the accuracy and consistency of the helical form the true essence of the helix was largely a function of the forming method, the experience of the operator, and the accuracy of the cut flight blank from which the helix was formed. The TruHelix™ Helical Screw Flight Forming System has been designed specifically to provide consistent, accurate output, and high productivity, with minimal skill input from the operator.

With this helical screw forming setup designed to form flights from 750 mm Outside Diameter (OD) upto 3000 mm OD, utilizing a TyroMR patented adjustable platen set for both mild steel and stainless steel plates suitable for thickness upto 32 mm, we are equipped to form helical screw flights for our customers with edge to edge matching witin few minutes.

Shaftless Screw Conveyor

Model SSC

Shaftless Screw Conveyors, Model SSC

Model SSC are a type of material handling equipment used to move bulk materials horizontally or at an inclination. Unlike traditional screw conveyors, shaftless spiral conveyors do not have a central shaft running through the middle of the spiral, which offers several advantages. These conveyors usually find their application for conveying most of the hygroscopic and difficult materials with high discharge rates. The design is well-suited for handling materials in environmentally sensitive applications, such as handling sludge or other materials in wastewater treatment plants.Here are some key features and benefits of shaftless spiral conveyors

Design

The screws are housed within a trough or casing that contains the material being fed. This trough can be opened or closed, depending on the specific requirements of the application.

Material Construction

Can be offered both in mild steel and stainless-steel construction.

Screw Design

No central shaft: The absence of a central shaft eliminates the risk of material buildup and blockages around the shaft, making these conveyors suitable for handling sticky or viscous materials.

Versatility

The shaftless design allows for a larger carrying capacity, as there is more space for bulk materials within the spiral. This makes them ideal for applications where high-capacity transport is required.- Shaftless spiral conveyors are versatile and can be used for various applications, such as wastewater treatment, industrial processes, food processing, and more.

Drive Options

Motor Types: Screw conveyors can be powered by various types of electric motor configurations. The choice of motor depends on factors such as the required capacity, speed, and the nature of the materials being conveyed.

Inlet and Outlet Options

Generally, these conveyors can be manufactured for customized inlet and outlet options.

Reduced Wear and Tear

Since there is no central shaft to cause friction, wear and tear on the conveyor components are minimized. This can lead to a longer operational life and less frequent replacement of parts.

Maintenance and Safety

Access Points: Consider designs that facilitate easy access for maintenance and cleaning.

Low Maintenance: The design simplifies maintenance by reducing the likelihood of material buildup and the associated wear and tear. This results in lower maintenance costs and increased reliability.

Safety Features: Incorporate safety features such as guards and emergency stops to ensure safe operation.

Capacity and Power Requirements

Capacity: The conveyor’s capacity is influenced by factors like the screw diameter, pitch, and rotational speed.

Power Requirements: The power needed to drive the conveyor depends on factors such as the material’s characteristics and the conveyor’s design parameters.

Optional Features on request

Special material of construction

Trough Liners (Stainless steel/Hardox/UHMWP)

Hardfacing on the screw flight

Sludge, Food processing, Animal feed, Solid waste management, Pulp, Chemicals, etc.

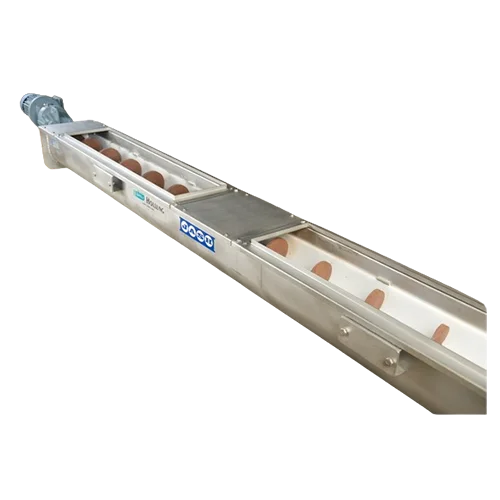

Stainless Steel Trough Screw Conveyor

Model STC

Shaftless Screw Conveyors, Model STC

Model STC are a type of material handling equipment used to move bulk materials horizontally or at an inclination. Unlike traditional screw conveyors, shaftless spiral conveyors do not have a central shaft running through the middle of the spiral, which offers several advantages. These conveyors usually find their application for conveying most of the hygroscopic and difficult materials with high discharge rates. The design is well-suited for handling materials in environmentally sensitive applications, such as handling sludge or other materials in wastewater treatment plants.Here are some key features and benefits of shaftless spiral conveyors:

Material Construction

Stainless Steel: The use of stainless steel in the construction of the trough and screw ensures corrosion resistance and hygiene, making these conveyors suitable for industries where cleanliness and sanitation are crucial, such as in food processing.

Screw Design

Helical Auger: The conveyor screw, also known as the auger, is a helical screw that rotates within the trough. The design and pitch of the screw flight affect the conveyor’s capacity, efficiency, and the type of material it can handle.

Versatility

Materials Handling: Stainless steel trough screw conveyors can handle a wide range of materials, including powders, granules, flakes, and other bulk materials.

Customization: Conveyors can be customized to suit specific applications, taking into consideration factors such as material type, flow rates, and space constraints.

Drive Options

Motor Types: Screw conveyors can be powered by various types of electric motor configurations. The choice of motor depends on factors such as the required capacity, speed, and the nature of the materials being conveyed.

Inlet and Outlet Options

The conveyors can be designed with different inlet and outlet configurations to accommodate specific material loading and discharge requirements.

Sanitary Design

Easy Cleaning: The smooth surfaces of stainless steel make it easy to clean, which is crucial in applications where sanitation is a priority, such as in the food and pharmaceutical industries.

Sealed Construction: Troughs can be designed with seals and gaskets to prevent material leakage and maintain a clean environment.

Maintenance and Safety

Access Points: Consider designs that facilitate easy access for maintenance and cleaning.

Safety Features: Incorporate safety features such as guards and emergency stop to ensure safe operation.

Capacity and Power Requirements

Capacity: The conveyor’s capacity is influenced by factors like the screw diameter, pitch, and rotational speed.

Power Requirements: The power needed to drive the conveyor depends on factors such as the material’s characteristics and the conveyor’s design parameters.

Optional Features on request

Special material of construction

Provision for clean in place (CIP)

Food Processing, Plastics, Chemicals, Petrochemicals, Pharmaceuticals, Distilleries, Breweries, Dosing and mixing, Paint and resins, Fertilizers, Sugar processing, Baby food processing, Solid waste management, etc.

Trough Screw Conveyor

Trough Screw Conveyors, Model TC

Our Mild steel trough screw conveyors, Model TC are similar to stainless steel trough screw conveyors in terms of their basic design and function, but they differ in the material used for construction. Mild steel, also known as carbon steel, is a common choice for troughs and screws in screw conveyors, especially when the application doesn’t require the corrosion resistance offered by stainless steel or process which doesn’t require a hygienic manufacturing setup.

Material Construction

Mild Steel (Carbon Steel): Mild steel is a cost-effective material that is often used in screw conveyor construction when corrosion resistance is not a primary concern. It’s suitable for various industrial applications.

Screw Design

Helical Auger: Similar to stainless steel screw conveyors, mild steel trough screw conveyors feature a helical screw that rotates within the trough. The screw design affects the conveyor’s performance and efficiency.

Versatility

Materials Handling: Mild steel screw conveyors can handle a wide range of materials, such as powders, granules, and bulk solids.

Customization: Like stainless steel conveyors, mild steel conveyors can be customized based on the specific requirements of the application.

Cost Effective Solutions

Mild steel is generally less expensive than stainless steel, making mild steel trough screw conveyors a cost-effective solution for applications where corrosion resistance is not critical.

Drive Options

Motor Types: Screw conveyors can be powered by various types of electric motor configurations. The choice of motor depends on factors such as the required capacity, speed, and the nature of the materials being conveyed.

Inlet and Outlet Options

The conveyors can be designed with different inlet and outlet configurations to accommodate specific material loading and discharge requirements.

Coating and Surface Treatments

While mild steel is more susceptible to corrosion compared to stainless steel, coatings and surface treatments (such as paint or galvanization) can be applied to provide some level of corrosion protection.

Maintenance and Safety

Access Points: Consider designs that facilitate easy access for maintenance and cleaning.

Safety Features: Incorporate safety features such as guards and emergency stops to ensure safe operation.

Capacity and Power Requirements

Capacity: The conveyor’s capacity is influenced by factors like the screw diameter, pitch, and rotational speed.

Power Requirements: The power needed to drive the conveyor depends on factors such as the material’s characteristics and the conveyor’s design parameters.

Optional Features on request

Special material of construction

Trough Liners (Stainless steel/Hardox/UHMWP)

Hardfacing on the screw flight

Hanger bearings

Coal handling, Fly Ash handling, Cement, Steel, Chemicals, Petrochemicals, Animal feed, Mining, Mineral processing, Foundries, Grain handling, Solid waste management, etc.

Tubular Screw Conveyor

Model TBC

Tubular Screw Conveyors, Model TBC

Our Tubular trough screw conveyors, Model TBC are a type of mechanical conveying system used to transport bulk materials in various industries. These conveyors consist of a rotating screw enclosed in a tubular casing or trough.

Casing Design

Tubular casing: The tubular casing provides containment for the materials being conveyed, preventing spillage and dust emissions.

It also offers protection for the screw, reducing wear and extending the life of the conveyor.

Material Construction

Can be offered both in mild steel and stainless-steel construction.

Screw Design

The screw is the central component responsible for moving materials. It typically consists of a helical flight mounted on a central shaft.

Versatility

Materials Handling: Mild steel screw conveyors can handle a wide range of materials, such as powders, granules, and bulk solids.

Customization: These conveyors can be customized based on the specific requirements of the application.

Drive Options

Motor Types: Screw conveyors can be powered by various types of electric motor configurations. The choice of motor depends on factors such as the required capacity, speed, and the nature of the materials being conveyed.

Inlet and Outlet Options

The conveyors can be designed with different inlet and outlet configurations to accommodate specific material loading and discharge requirements.

Maintenance and Safety

Access Points: Consider designs that facilitate easy access for maintenance and cleaning.

Safety Features: Incorporate safety features such as guards and emergency stops to ensure safe operation.

Capacity and Power Requirements

Capacity: The conveyor’s capacity is influenced by factors like the screw diameter, pitch, and rotational speed.

Power Requirements: The power needed to drive the conveyor depends on factors such as the material’s characteristics and the conveyor’s design parameters.

Cement plants, Thermal power plants, Floor mills, Rice mills, Animal feed, Bin and silo discharges, Grain storage and handling, Bulk solids handling, etc.